- Home >

- To go further >

- Practical cases >

- Aerosud

Aerosud

Case study Critical Chain: Develop new products on time

The Theory of Constraints was already successfully implemented in the process of improving production performance at Aerosud.

In order to respond to the strong productivity gains obtained as well as to new markets and projects, it was decided to set up the Critical Chain Project Management (CCPM) methodology for new product development projects.

A first Critical Chain attempt several years before was unsuccessful.

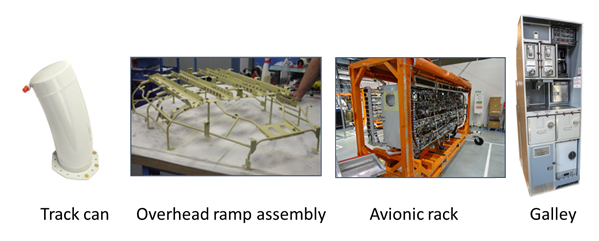

Aerosud, created in 1990, is a South African aeronautical equipment supplier (~ 700 people), counting among its customers Airbus, Boeing, Safran, etc.

Aerosud offers design, development and production services for aviation-related programs, including structural manufacturing of aircraft, composite products, thermoplastics and others.

In order for the implementation of the Critical Chain to be a real company project, the key players on the site were trained in the Critical Chain method and tools, while all project resources were made aware of the general principles of the method.

All the projects in the new product development portfolio were planned (creation of WBS *) and passed under Critical Chain, in order to quickly identify the key stages of the different projects to guarantee an end to the planned deadline.

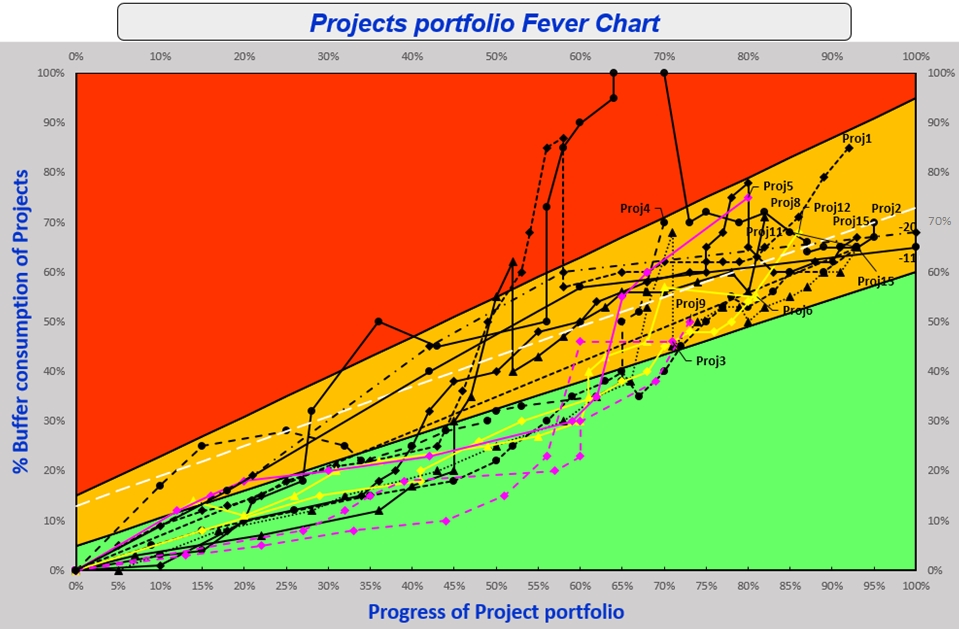

Management according to the Critical Chain of individual projects and of the project portfolio, with the use of mascots and the establishment of Fever Charts, and in particular the Fever Charts as a tool to help decision-making (dynamic arbitration of conflicts of resources).

Examples of mascots used by Aerosud

Seduced by the method, the scope was quickly widened with the application of the method to all types of company projects, in particular to Continuous Improvement projects, such as the complete reorganization of a warehouse (physical and functioning ), and upgrading the plant's ERP system.

The implementation of the method and the new principles for managing the portfolio made it possible to control the development of new products and quickly obtain a rate of compliance with deadlines well above 90%.

The implementation was a success, and still is since the Critical Chain is still used after years.

This is a practical case performed with Marris Consulting

This is a practical case performed with Marris Consulting

Maine Montparnasse Tower, 27th floor

33 avenue du Maine

75755 PARIS cedex 15